Food industry

Dairy

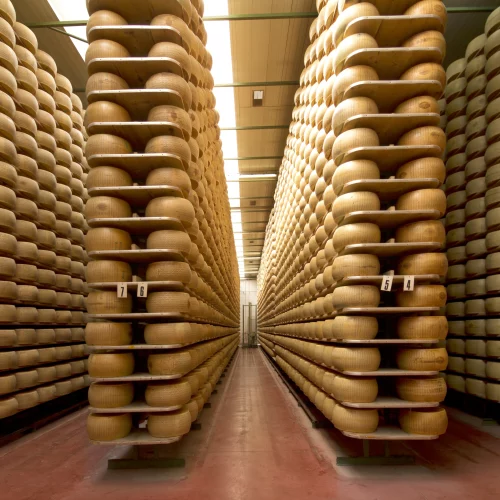

Controlling the cold temperature at every stage of the production cycle is a critical issue for the dairy processing industry. With our experience we are able to provide the best solutions, ensuring controlled temperature and air filtration during all stages of processing milk and its derivatives, up to the processing and packaging rooms. By assessing the needs of the customer and the product, we manage the thermo-hygrometric parameters from drying to ripening, maturation and maturing of the cheeses.Fruit and vegetables

For storage, fruit and vegetables require not only temperature control, but above all the specific percentage of humidity in the environment, depending on the product. This allows the weight, consistency, freshness, flavour and appearance of the product to be kept under control during ripening and storage. Each project we have implemented has been tailor-made according to the needs and requirements of the product and has enabled us to fully satisfy our customers' needs.Meat and cold cuts

Refrigeration plays a fundamental role in the preservation and subsequent processing of meat, requiring advanced technological solutions. The temperature after slaughtering must be lowered in a continuous and rapid manner in order to keep the organoleptic properties of the product intact. Cold management also affects the drying, curing and storage process of cold meats, hams and speck. Our expertise allows us to design tailor-made plants based on the customer's needs and requirements.Fish

Fish products need perfect preservation to maintain their original freshness. Salt water is notoriously corrosive and the plant must not be affected. Very often flake ice is used for fish preservation, for which special plants of different powers are required.Realizations

Some achievements in the sector

Look at the photo gallery to discover some examples of the systems created by IFI Service for this sector